- Engine MRO Services

- Engine Capabilities

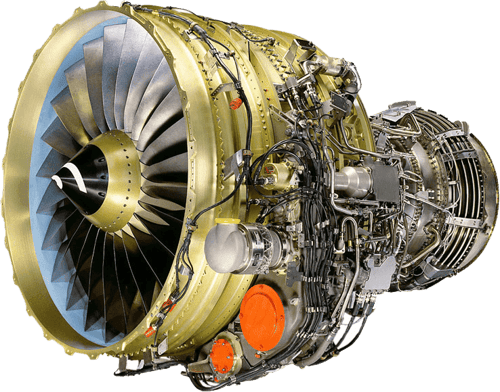

- CFM56-2/-3/-5/-7

CFM International

CFM56-2/-3/-5/-7 Engines

Optimize Reliability & Efficiency of the Best-Selling Commercial Jet Engine

The CFM56 is a family of high-bypass turbofan engines, jointly developed by CFM International - a 50/50 partnership between GE and Safran Aircraft Engines - and offered in five models with thrust ranging from 18,500 to 34,000 lb. It's the best-selling jet engine in commercial aviation history, powering the Airbus A320 family and all Boeing 737 variants. Airbus A320 primarily uses the CFM56-5B, the only engine compatible with all A320 models, and Boeing 737 Next-Generation exclusively uses the CFM56-7B.

Pem-Air provides extensive experience in Engine Maintenance Services for the Following CFM56 Jet Engine Variants:

CFM56-2

Common in military applications and known as the F108; specifically in the KC-135, the E-6 Mercury, and some E-3 Sentry

CFM56-3

Designed for Boeing 737 Classic series - 737-300/-400/-500

CFM56-5

-5A and especially the -5B series that can power every model in the A320 family - A318/A319/A320/A321

CFM56-7

-7B powering the Boeing 737 Next Generation -600/-700/-800/-900 series

Our team of skilled MRO technicians boasts extensive experience and specialized expertise in working with CFM56 engines. From routine maintenance to complex repairs and complete overhauls, our technicians are equipped to provide meticulous care and attention to detail for your CFM turbofans, ensuring optimal performance and longevity. We collaborate closely with our clients to develop personalized service plans that minimize downtime, reduce operational costs, and extend the lifespan of their engine assets.

Jet Engine Services We Offer:

Light Maintenance (Minimal Penetration):

- Boro-blending/Borescope blade blending for minor blade imperfections

- Variable Stator Vanes (VSV)/Variable Bleed Valves (VBV), static rigging

- Engine preservations

- Borescope, digital measurement, and Non-Destructive Testing (NDT) Inspection

- Troubleshooting Engine Performance

Hospital Visit (Check/Repair):

- HPC repair/Top Case repair

- Decoking of oil lines

- Low-Pressure Turbine (LPT), Booster, High-Pressure Turbine (HPT) module changes

Performance Restoration (Gas Path):

- HPT shroud grinding and refurbishing, repairing shroud components

- High-Pressure Compressor (HPC) high-speed grinding

- HPT high-speed grinding

- Low-Pressure Compressor (LPC)/HPC/HPT/LPT rotor balancing, dynamic and static

- Moment weighing of blades, 1+2 HPC, Stage 1+2 HPT, All LPT Blades

- Comprehensive vibration/trim balance assessments.

Full Restoration/Overhaul (All Modules):

- Main Gearbox, Accessory Gearbox (AGB), and Transfer Gearbox (TGB) replacement or overhaul

- VSV stage to stage rigging

- VBV doors and actuator rigging

- Full Quick Engine Change (QEC) swaps, conversions

- Fan disk and blade replacement

- Line-Replaceable Units (LRU) replacement

- Full module repairs

Additional Services We Offer:

- Airworthiness Directive (AD) and Service Bulletin (SB) compliance services

- Engine removal and installation

- Engine management

- Field Services and AOG support worldwide

- Engine Test Cell runs

- On-wing Testing Maximum Power Assurance (MPA) certification

- FAA/EASA dual release capability

- Engine Leasing

Elevate Your Experience

Contact us today for more information about our company and services

© 2026 Pem-Air Turbine Engine Services, LLC, Pem-Air, LLC, Pem-Air Engine Lease, LLC

.png)

.png)

-1.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)